Engine oil is more than a routine maintenance item. It is the protective layer that separates metal parts spinning thousands of times per minute. When oil is missing, even briefly, internal components begin to grind, overheat, and wear at an accelerated rate.

Many engines can survive short oil pressure drops, but running without oil for longer periods often leaves permanent damage behind.

The challenge is that oil-related damage does not always announce itself immediately. Some engines keep running while internal wear quietly builds.

Others fail suddenly with loud noise and total shutdown. Between these extremes lies a wide range of warning signs that can reveal what is happening inside the engine.

Being able to tell whether an engine has been damaged by lack of oil helps owners decide the next step.

Some situations allow limited repair. Others point toward major rebuilding or replacement. A structured evaluation, starting with simple observations and moving toward deeper checks, offers clarity without guesswork or unnecessary expense.

Table of Contents

What Happens Inside An Engine When Oil Is Missing

Oil loss affects multiple systems at once. The damage pattern depends on how long the engine ran dry and under what conditions.

Loss Of Lubrication And Heat Control

Oil forms a thin film between moving parts. Without it, friction increases dramatically. Metal surfaces begin to scrape rather than glide.

At the same time, oil normally carries heat away from bearings, pistons, and camshafts. Without oil, temperatures spike quickly.

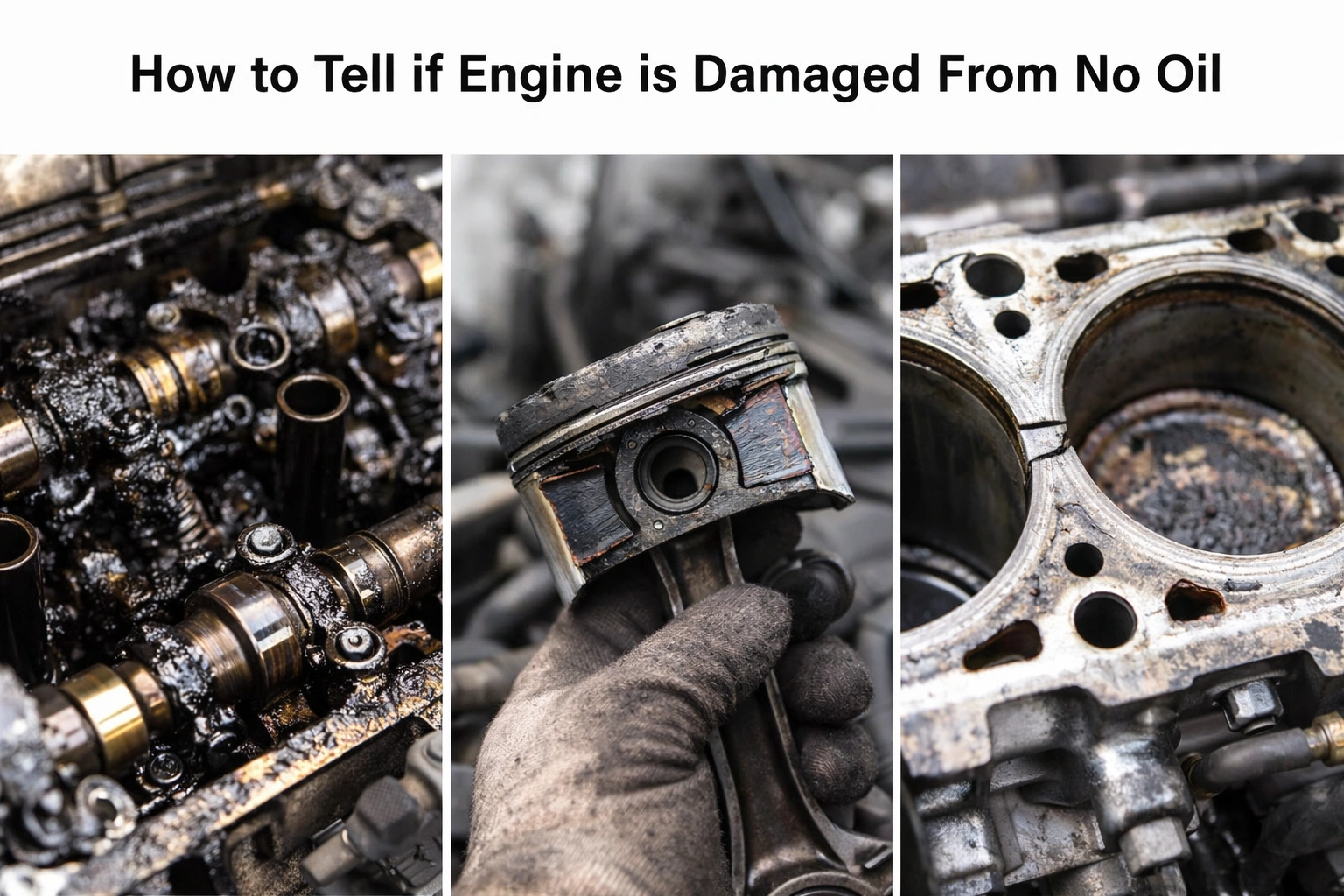

Bearing And Journal Damage

Crankshaft and connecting rod bearings rely entirely on pressurized oil. When pressure drops, these bearings are often the first to fail.

Once bearing material wears away, clearances increase, leading to knocking and loss of oil pressure.

Piston And Cylinder Scoring

Pistons depend on oil to reduce friction against cylinder walls. Without oil, scoring and scuffing occur.

This damage reduces compression and increases oil consumption once oil is restored.

Camshaft And Valve Train Wear

Cam lobes, lifters, and rocker arms experience heavy contact forces. Oil starvation here causes rapid surface wear.

Valve timing and lift become inconsistent, affecting power and idle quality.

Early Warning Signs After Running Without Oil

Some symptoms appear soon after oil loss, even if the engine still runs.

Warning Lights And Oil Pressure Alerts

The oil pressure warning light is often the first indicator. If it came on while driving, internal damage may already have begun.

Ignoring this warning greatly increases the chance of severe engine wear.

New Engine Noises

Knocking, ticking, or grinding sounds point toward metal-to-metal contact.

A deep knocking sound often signals bearing damage, while lighter ticking may indicate valve train wear.

Overheating Without External Cause

Oil helps regulate temperature. Without it, engines overheat quickly even if the cooling system is working.

Unexplained overheating following oil loss is a serious sign.

Rough Idle Or Reduced Power

Loss of compression or valve train damage leads to uneven combustion.

The engine may shake, hesitate, or feel noticeably weaker.

Physical And Mechanical Checks That Reveal Damage

Several checks help confirm whether damage has occurred.

Checking Oil Condition After Refilling

Drain the oil after running briefly and inspect it closely.

Metal flakes, glitter-like particles, or burnt smell suggest internal wear. Clean oil indicates less severe damage.

Inspecting The Oil Filter

Cutting open the oil filter reveals trapped debris.

Metal shavings or bearing material inside the filter strongly indicate engine damage.

Listening For Changes Under Load

Light acceleration that produces knocking or rattling sounds suggests bearing or piston damage.

Noise that increases with engine speed is especially concerning.

Compression And Leak-Down Testing

Compression tests reveal whether pistons and valves are sealing properly.

Low or uneven readings across cylinders often follow oil starvation. Leak-down tests pinpoint where pressure escapes.

Oil Pressure Testing

Installing a mechanical gauge confirms actual oil pressure.

Low pressure after refilling oil often points to worn bearings or damaged oil pump components.

Advanced Symptoms Of Severe Oil Starvation

When damage progresses, signs become harder to ignore.

Persistent Engine Knock

A constant knocking sound that does not fade with warm-up indicates serious bearing wear.

This condition rarely improves and often worsens rapidly.

Excessive Oil Consumption

Damaged piston rings and cylinder walls allow oil to enter the combustion chamber.

Blue exhaust smoke and frequent oil loss follow.

Engine Seizure Or Sudden Shutdown

In extreme cases, friction and heat cause parts to lock together.

A seized engine will not turn over and requires major repair or replacement.

Check Engine Codes Related To Timing

Camshaft and crankshaft sensors may detect irregular rotation caused by worn components.

These codes often accompany mechanical damage.

Differentiating Minor Damage From Major Failure

Not all oil starvation results in total engine loss. Severity matters.

Short Oil Pressure Drop Versus Extended Operation

Brief oil loss at idle may cause limited wear.

Extended driving at speed without oil almost always causes major damage.

Noise That Fades Versus Noise That Persists

Light ticking that fades after oil refill may indicate minimal valve train wear.

Persistent knocking signals deeper internal damage.

Stable Oil Pressure Versus Falling Pressure

Normal pressure after refilling oil suggests bearings survived.

Pressure that drops as the engine warms points toward bearing clearance issues.

Repair Options Based On Damage Level

Repair decisions depend on findings, not hope.

Situations Where Repair May Be Possible

Minor valve train wear, oil pump issues, or temporary pressure loss may be repairable.

Replacing damaged components early prevents further wear.

Partial Engine Rebuild Scenarios

Bearing replacement, crankshaft polishing, or piston ring service may restore function.

These repairs require engine removal and skilled labor.

Full Engine Replacement Considerations

Severe bearing damage, cylinder scoring, or seizure often make replacement more practical.

Modern engines are frequently replaced rather than rebuilt due to cost efficiency.

Risks Of Continuing To Drive After Oil Damage

Driving a damaged engine increases overall loss.

Accelerated Wear Progression

Once damage begins, it spreads quickly.

Metal debris circulates and damages other components.

Sudden Failure Risk

Engines weakened by oil starvation can fail without warning.

Loss of power at speed creates safety concerns.

Increased Repair Costs

Delayed action allows repairable damage to become catastrophic.

Early diagnosis limits expense.

How Long An Engine Can Survive Without Oil

There is no safe duration.

Seconds Versus Minutes

Engines can suffer damage in seconds under load.

Minutes without oil often result in permanent wear.

Engine Design Differences

Some engines tolerate brief oil pressure loss better due to bearing design or materials.

No engine is immune.

Preventing Oil-Related Engine Damage

Prevention remains far easier than repair.

Regular Oil Level Checks

Checking oil regularly catches leaks or consumption early.

Low oil warnings should never be ignored.

Timely Oil Changes

Fresh oil maintains proper viscosity and protection.

Old oil breaks down and loses effectiveness.

Addressing Leaks Promptly

Oil leaks reduce available lubrication over time.

Small leaks often grow quickly.

Monitoring Warning Lights

Oil pressure lights demand immediate shutdown.

Continuing to drive risks total engine loss.

When Professional Diagnosis Is Necessary

Some evaluations require expert tools.

Internal Inspection With Borescope

Technicians can inspect cylinder walls and pistons without disassembly.

This reveals scoring and wear clearly.

Oil Analysis Testing

Laboratory oil analysis identifies metal content and wear patterns.

This method confirms internal damage accurately.

Experienced Interpretation Of Symptoms

Trained technicians recognize sound patterns and pressure behavior.

Accurate diagnosis prevents unnecessary replacement.

Final Thoughts

Running an engine without oil is one of the most damaging events a vehicle can experience. The effects range from light wear to complete failure, depending on duration, load, and engine design. Clear signs such as knocking sounds, low oil pressure, metal debris, and compression loss reveal whether damage has occurred.

A methodical approach, starting with basic inspection and progressing to pressure and compression testing, removes uncertainty. Acting early often saves significant cost and prevents sudden breakdowns. Ignoring symptoms almost always leads to worse outcomes.

Engines rely on oil for survival. Once that protection disappears, time becomes the enemy. Careful evaluation and prompt decisions are the difference between manageable repair and irreversible damage.

- How To Reset The Maintenance Light On Toyota Tacoma - February 6, 2026

- What Does ECO On A Car Mean And How It Affects Mileage - February 6, 2026

- How To Reset Traction Control Light Safely And Correctly - February 6, 2026